AspenTech公司于近日发布了全新的软件版本AspenONE V9.0,旗下所有产品(包括Aspen Plus,Aspen HYSYS,Aspen EDR等)均从V8版升级到V9版,重大更新包括:

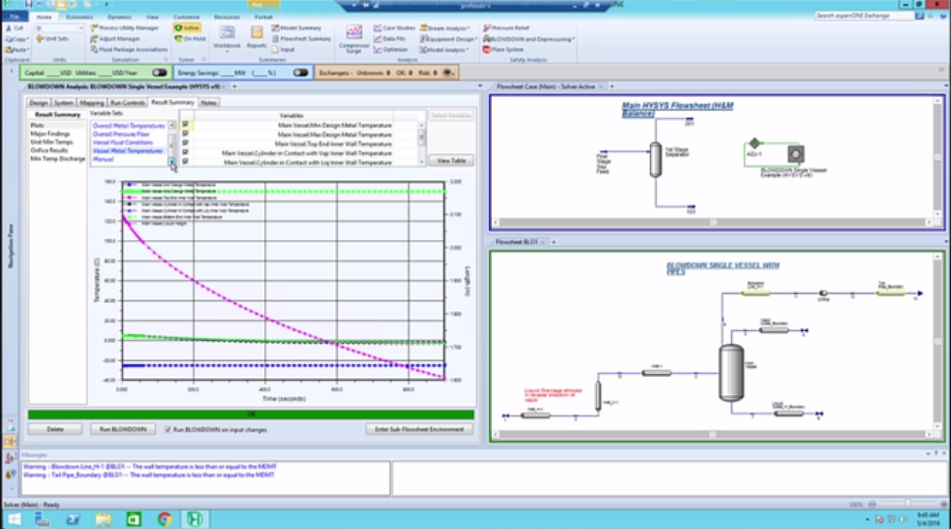

1、凭借在世界各地400多个项目有着出色表现的业界领先的Aspen HYSYS® BLOWDOWN™技术,为您的泄压工作带来革命性改变。

2、运用Aspen HYSYS中显著改进Excel界面的交互及案例研究工具,大大节省更新炼油厂计划模型的时间。

3、通过Aspen HYSYS中的Sulsim™ Sulfur Recovery帮助分析并解决硫磺回收装置的故障,增加正常运行时间,遵守相关法规。

4、通过Aspen HYSYS和Aspen Plus®中新的塔分析功能实现塔水力学数据的可视化,提高产品质量和产量。

5、通过新的Aspen DMC3 Builder建立和部署所有AspenTech APC控制器,提升效率达30%。

6、通过Aspen Fleet Optimizer中最新的Map Monitor功能实现调度可视化。

7、简化从Aspen Custom Modeler导出定制模型到Aspen Plus和Aspen HYSYS。

文章源自云智设计-https://www.cidrg.com/news/event/435.html

Aspen HYSYS V9 于2016年5月25日全球发布文章源自云智设计-https://www.cidrg.com/news/event/435.html

文章源自云智设计-https://www.cidrg.com/news/event/435.html

Aspen HYSYS V9

BEDFORD, Mass. — May 25, 2016 — Aspen Technology, Inc. (NASDAQ: AZPN), a leading provider of software andservices to the process industries, today announced the general availability of aspenONEEngineering and aspenONE Manufacturing and Supply Chain Version 9 software.The latest release gives firmsin the Oil, Gas, Refining, Chemicals, Engineering & Construction and otherprocess industries the integrated, streamlined workflows that help them savemillions of dollars.文章源自云智设计-https://www.cidrg.com/news/event/435.html

Innovations in theaspenONE V9 release help push the limits of asset performance, empowering usersto design and troubleshoot with confidence, improve reliability by enablinggreater insights into process constraints, on-board new users faster and makeprocess safety consistent and continuous throughout the entire asset lifecycle. AspenTech’s latest softwarerelease continues to provide a holistic foundation for operational excellence by giving manufacturers:文章源自云智设计-https://www.cidrg.com/news/event/435.html

Improved analysis capabilities. Insight into key processes enables better, faster andmore profitable problem solving.文章源自云智设计-https://www.cidrg.com/news/event/435.html

- Distillation columns are notoriously hard to operate optimally, resulting in losses in product and quality, and increased OPEX. With the new Column Analysis technology in Aspen HYSYS and Aspen Plus, engineers can readily analyze hydraulic performance and test operating parameters, resulting in up to 20 percent improvements in energy savings, and millions of potential dollars in improved product quality and throughput.

- In an emergency, lives and billions of dollars’ worth of assets are at stake. Over 400 projects have used industry-leading BLOWDOWN Technology, now part of Aspen HYSYS, to save significant CAPEX on oil, gas and LNG projects.

Better model-based decision support.Consistent,rigorous models drive process improvements that improve margins and reducecapital and operating costs.文章源自云智设计-https://www.cidrg.com/news/event/435.html

- Improved integration and workflow in the new aspenONE refinery planning model update enables process engineers to update planning models, so planners can increase profit with easy, accurate refinery-wide profit margin analysis – by as much as 10 percent, or $20 million annually per refinery site.

- Sulsim Sulfur Recovery in Aspen HYSYS ensures compliance with environmental regulations, reduces costs, and meets product specifications under changing feed and operating conditions, while simultaneously debottlenecking the gas plant.

- The latest Custom Modeling innovations enable process engineers to simplify the incorporation of custom models into Aspen Plus, reducing time-to-market for specialty chemicals producers by speeding up modeling of key processes.

- Schlumberger and AspenTech have collaborated to provide the latest link between OLGA software and Aspen HYSYS,expanding asset-wide modeling to maximize production without compromising safety in the upstream. In addition, new mercury partitioning capabilities in Aspen HYSYS track and reduce hazardous contaminants, increasing equipment reliability and lowering maintenance costs.

Streamlined APC application workflows with anintuitive, ribbon based user interface. TheaspenONE Manufacturing and Supply Chain V9 updates include the new Aspen DMC3Builder that can increase efficiency up to 30 percent by building anddeploying all AspenTech APC controllers from start to finish on one intuitivetool. The workflow oriented design builds controllers faster and enables moreengineers, preserving process knowledge and increasing APC project efficiency.

Extension of scheduling beyond the refinery gate. Meeting fuel demand while minimizing costs and maximizingmargins is made possible with the ability to evaluate and optimize supply chaintradeoffs. The new Map Monitor in Aspen Fleet Optimizer (AFO) improvesscheduler visualization with an interactive web-based mapping application,providing real-time, accurate information that streamlines fuel distribution.文章源自云智设计-https://www.cidrg.com/news/event/435.html

The V9 release of aspenONE Engineering andManufacturing & Supply Chain software is availableimmediately. Customers on the aspenONE Licensing Model can upgrade to the new versionfor no additional cost. For more information, visit http://www.aspentech.com/products/v9-release/.文章源自云智设计-https://www.cidrg.com/news/event/435.html

Supporting Quotes文章源自云智设计-https://www.cidrg.com/news/event/435.html

Josh Fredberg, SeniorVice President, Products & Marketing, AspenTech

“The aspenONE V9 software release is a continuation of AspenTech’s commitment to transform process manufacturing with innovative technology that drivesthe highest possible returns across the entire asset lifecycle. We are pleased todeliver the latest release of the integrated aspenONE software system that enables sustainable operational excellence to driveprofitable outcomes.”

Benito CaamaňoNieves, Technologist, Repsol Technology Center

“We have used the Acid Gas Cleaning and Column Analysistechnology in Aspen HYSYS V9 to optimize acid gas treating processspecifications and costs in our units, while simultaneously evaluating theimpact of process changes on column hydraulics. Repsol intends to introduce thehydraulic plots now available in the latest version of aspenONE Engineeringinto our standard amine reports as a best practice for monitoring and improvingthe performance of columns.”

HarendraSingh, Engineering Manager, NPCC

“The new BLOWDOWN functionality within Aspen HYSYSoffers a one stop solution for facilities blowdown and minimum temperaturestudies. It's a step in the right direction from conventional depressuring utility as it usesthe industry benchmark Imperial College correlations for estimation of minimummetal temperatures. Many new features, including the ability to model detailedsystem geometry, are added and the workflow is very user-friendly. Overall, itshould enhance the efficiency of our process engineers.”

1F

不知道软件嵌入的Sulsim软件是全部还是其中的一部分?据说Sulsim比VMGSim和Promax在硫磺回收方面的精确度都高,期待中……